Mfundo yathu yotitsogolera ndikulemekeza mapangidwe a kasitomala pomwe timagwiritsa ntchito luso lathu lopanga kupanga ma PCB omwe amakwaniritsa zomwe kasitomala akufuna. Zosintha zilizonse pamapangidwe apachiyambi zimafuna chilolezo cholembedwa kuchokera kwa kasitomala. Akalandira ntchito yopanga, mainjiniya a MI amawunika mosamala zikalata zonse ndi chidziwitso choperekedwa ndi kasitomala. Amazindikiranso kusiyana kulikonse pakati pa data ya kasitomala ndi luso lathu lopanga. Ndikofunikira kumvetsetsa bwino zomwe kasitomala akufuna kupanga komanso zomwe akufuna kupanga, kuwonetsetsa kuti zonse zomwe zikufunika zikufotokozedwa momveka bwino komanso kuti zitha kuchitika.

Kukonza mapangidwe a kasitomala kumaphatikizapo masitepe osiyanasiyana monga kupanga stack, kusintha kukula kwa kubowola, kukulitsa mizere yamkuwa, kukulitsa zenera la chigoba cha solder, kusintha zilembo pazenera, ndi kupanga masanjidwe. Zosinthazi zimapangidwa kuti zigwirizane ndi zosowa zonse zopanga komanso zomwe kasitomala amapangira.

Njira yopangira PCB (Printed Circuit Board) ikhoza kugawidwa m'masitepe angapo, iliyonse ikuphatikiza njira zosiyanasiyana zopangira. Ndikofunikira kudziwa kuti njirayo imasiyanasiyana malinga ndi kapangidwe ka bolodi. Zotsatirazi zikuwonetsa ndondomeko ya PCB yamitundu yambiri:

1. Kudula: Izi zimaphatikizapo kudula mapepala kuti agwiritse ntchito kwambiri.

2. Internal Layer Production: Sitepe iyi ndi yopangira gawo lamkati la PCB.

- Kuchiza: Izi zimaphatikizapo kuyeretsa gawo lapansi la PCB ndikuchotsa zonyansa zilizonse.

- Lamination: Apa, filimu yowuma imatsatiridwa ndi gawo lapansi la PCB, kukonzekera kusamutsa kwazithunzi.

- Kuwonekera: Gawo laling'ono lophimbidwa limayang'aniridwa ndi kuwala kwa ultraviolet pogwiritsa ntchito zida zapadera, zomwe zimasamutsa chithunzi cha gawo lapansi kufilimu youma.

- Gawo lowonekera limapangidwa, lokhazikika, ndipo filimuyo imachotsedwa, ndikumaliza kupanga bolodi lamkati.

3. Kuyang'ana M'kati: Gawoli ndiloyesa ndikukonza mabwalo a board.

- AOI Optical scanning imagwiritsidwa ntchito kuyerekeza chithunzi cha board ya PCB ndi data ya bolodi yabwino kuti muwone zolakwika monga mipata ndi zobowoka pachithunzi cha bolodi. - Zowonongeka zilizonse zomwe AOI zapeza zimakonzedwa ndi ogwira nawo ntchito.

4. Lamination: Njira yophatikiza zigawo zingapo zamkati kukhala bolodi limodzi.

- Browning: Sitepe iyi imalimbitsa mgwirizano pakati pa bolodi ndi utomoni ndikuwongolera kunyowa kwa mkuwa.

- Riveting: Izi zimaphatikizapo kudula PP pakukula koyenera kuphatikiza bolodi lamkati ndi PP yofananira.

- Kutentha Kutentha: Zigawozi zimapanikizidwa ndi kutentha ndikukhazikika kukhala gawo limodzi.

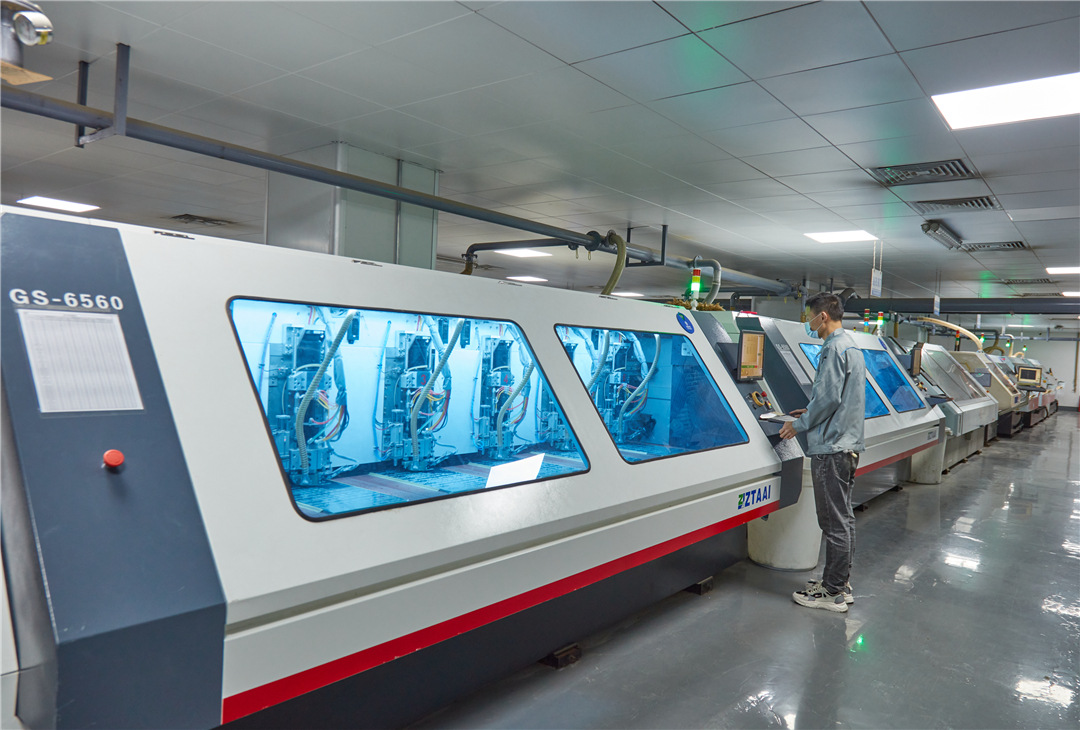

5. Kubowola: Makina obowola amagwiritsidwa ntchito popanga mabowo amitundu yosiyanasiyana ndi makulidwe pa bolodi malinga ndi zomwe kasitomala akufuna. Mabowo awa amathandizira kukonza mapulagini wotsatira ndikuthandizira kutulutsa kutentha kuchokera pagulu.

6. Pulatiyiti Yamkuwa Yoyambira: Mabowo obowoleredwa pa bolodi amakutidwa ndi mkuwa kuti awonetsetse kuti zigawo zonse za bolodi zikuyenda bwino.

- Deburring: Sitepe iyi ikuphatikizapo kuchotsa ma burrs m'mphepete mwa bowo la bolodi kuti musatseke bwino mkuwa.

- Kuchotsa Glue: Chotsalira chilichonse cha guluu mkati mwa dzenje chimachotsedwa kuti chiwonjezere kumamatira panthawi ya micro-etching.

- Hole Copper Plating: Sitepe iyi imawonetsetsa kuti magawo onse a bolodi amapangidwa ndikuwonjezera makulidwe amkuwa.

7. Outer Layer Processing: Njirayi ikufanana ndi ndondomeko yamkati yamkati mu sitepe yoyamba ndipo yapangidwa kuti izithandizira kupanga dera lotsatira.

- Chithandizo chisanadze: Pa bolodi amatsukidwa ndi pickling, akupera, ndi kuyanika kuti filimu youma kumamatira.

- Lamination: Kanema wowuma amatsatiridwa ndi gawo lapansi la PCB pokonzekera kusamutsa kwazithunzi.

- Kuwonekera: Kuwonekera kwa kuwala kwa UV kumapangitsa kuti filimu yowuma pa bolodi ilowe m'malo a polymerized komanso opanda polymerized.

- Chitukuko: Kanema wowuma wopanda polymer imasungunuka, ndikusiya kusiyana.

8. Secondary Copper Plating, Etching, AOI

- Sekondale Copper Plating: Chitsanzo electroplating ndi mankhwala mkuwa ntchito amachitidwa pa madera mu mabowo osaphimbidwa ndi filimu youma. Gawoli limaphatikizaponso kupititsa patsogolo madulidwe ndi makulidwe amkuwa, kutsatiridwa ndi plating ya malata kuti ateteze kukhulupirika kwa mizere ndi mabowo pa etching.

- Etching: Mkuwa woyambira mufilimu yakunja yowuma (filimu yonyowa) imachotsedwa pochotsa filimu, etching, ndi njira zochotsera malata, kumaliza dera lakunja.

- Outer Layer AOI: Mofanana ndi AOI yamkati, AOI Optical scanning imagwiritsidwa ntchito kuzindikira malo omwe ali ndi vuto, kenako amakonzedwa ndi ogwira nawo ntchito.

9. Kugwiritsa Ntchito Mask Mask: Njira iyi ikuphatikizapo kugwiritsa ntchito chigoba cha solder kuteteza bolodi ndikupewa oxidation ndi zina.

- Pretreatment: The bolodi undergoes pickling ndi akupanga kutsuka kuchotsa oxides ndi kuonjezera mkuwa pamwamba roughness.

- Kusindikiza: Solder resist inki imagwiritsidwa ntchito kuphimba madera a bolodi la PCB omwe safuna kutenthetsa, kupereka chitetezo ndi kutsekereza.

- Kuphikatu: Chosungunulira mu inki ya solder chigoba chauma, ndipo inkiyo imawumitsidwa pokonzekera kuwonetseredwa.

- Kuwonekera: Kuwala kwa UV kumagwiritsidwa ntchito kuchiritsa inki yogulitsa chigoba, zomwe zimapangitsa kuti pakhale polima yapamwamba kwambiri ya ma cell kudzera mu photosensitive polymerization.

- Kukula: Njira ya sodium carbonate mu inki yopanda polymerized imachotsedwa.

- Kuphika pambuyo: Inkiyo yaumitsidwa.

10. Kusindikiza Malemba: Sitepe iyi ikuphatikizapo kusindikiza malemba pa bolodi la PCB kuti awoneke mosavuta panthawi yogulitsa.

- Pickling: Pamwamba pa bolodi amatsukidwa kuti achotse okosijeni ndikuwonjezera kumamatira kwa inki yosindikiza.

- Kusindikiza Malemba: Zolemba zomwe mukufuna zimasindikizidwa kuti zithandizire njira zowotcherera.

11.Kuchiza Pamwamba: Chovala chamkuwa chopanda kanthu chimayang'aniridwa ndi chithandizo chapamwamba potengera zofuna za makasitomala (monga ENIG, HASL, Silver, Tin, Plating golide, OSP) kuteteza dzimbiri ndi okosijeni.

Mbiri ya 12.Board: Bolodi imapangidwa molingana ndi zofuna za kasitomala, kuwongolera SMT patching ndi kusonkhana.

14. Final Quality Check (FQC): Kuyang'ana mwatsatanetsatane kumachitika mukamaliza njira zonse.