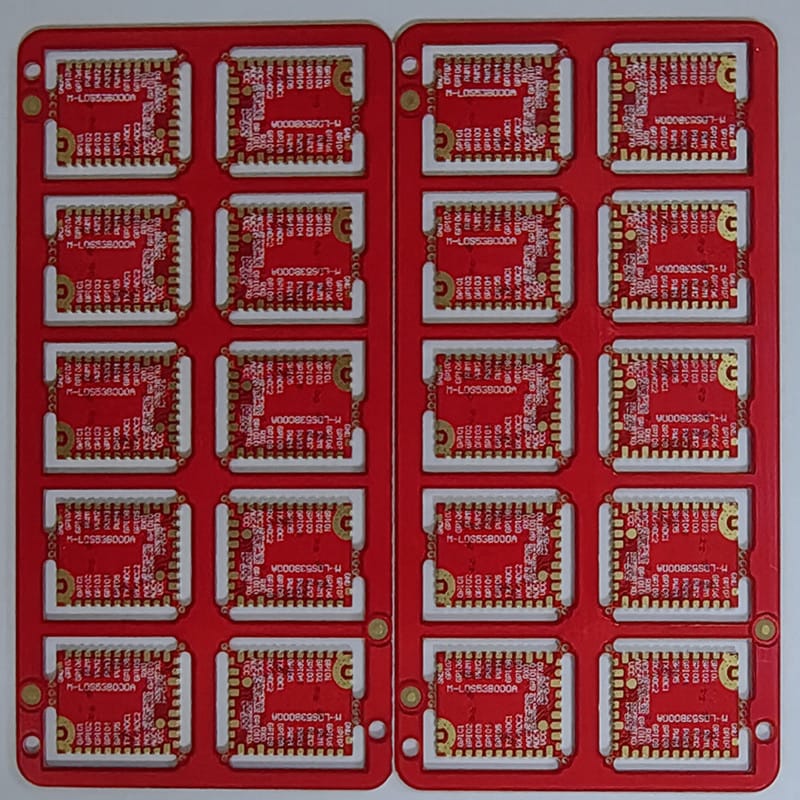

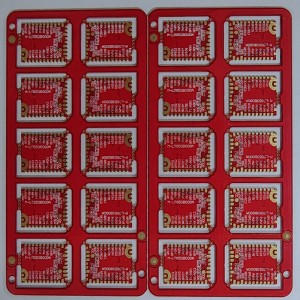

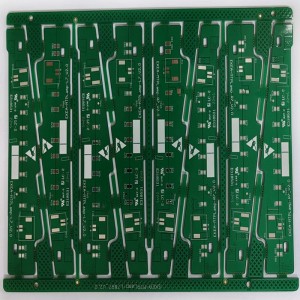

Ma prototype osindikizidwa matabwa RED solder chigoba castellated mabowo

Zogulitsa:

| Zida Zoyambira: | FR4 TG140 |

| Makulidwe a PCB: | 1.0+/-10% mm |

| Chiwerengero cha Masanjidwe: | 4L |

| Makulidwe a Copper: | 1/1/1/1 oz |

| Chithandizo chapamwamba: | ENIG 2U” |

| Maski a Solder: | Chofiira chonyezimira |

| Silkscreen: | Choyera |

| Njira yapadera : | Pth theka mabowo m'mphepete |

Kugwiritsa ntchito

Njira zopangira ma half holes ndi:

1. Pangani dzenje la theka la mbali ndi chida chodulira chooneka ngati V kawiri.

2. Kubowola kwachiwiri kumawonjezera mabowo owongolera kumbali ya dzenje, kumachotsa khungu lamkuwa pasadakhale, kumachepetsa ma burrs, ndikugwiritsa ntchito odula groove m'malo mobowola kuti akwaniritse liwiro ndi liwiro.

3. Imirira mkuwa kuti electroplate gawo lapansi, kotero kuti wosanjikiza mkuwa ndi electroplated pa dzenje dzenje la dzenje m'mphepete mwa bolodi.

4. Kupanga kwa dera lakunja wosanjikiza pambuyo pa kuyanika, kuwonekera, ndi chitukuko cha gawo lapansi motsatizana, gawo lapansili limayikidwa pazitsulo zamkuwa zachiwiri ndi plating ya malata, kotero kuti wosanjikiza mkuwa pa khoma la dzenje la dzenje lozungulira pamphepete mwa nyanja. bolodi ndi wandiweyani ndipo wosanjikiza mkuwa yokutidwa ndi wosanjikiza malata kukana dzimbiri;

5. Kupanga theka la dzenje kudula dzenje lozungulira m'mphepete mwa bolodi pakati kuti mupange theka la dzenje;

6. Mu sitepe yochotsa filimuyo, filimu yotsutsa-electroplating yomwe imakanizidwa panthawi ya filimuyi imachotsedwa;

7. Kujambula gawo lapansi kumakhazikika, ndipo mkuwa wowonekera pamtunda wakunja wa gawo lapansi umachotsedwa ndi etching;

8. Tini akuvula gawo lapansi amachotsedwa malata, kotero kuti malata pakhoma la theka la dzenje akhoza kuchotsedwa, ndipo wosanjikiza wamkuwa pakhoma la theka la dzenje amawonekera.

9. Mukapanga, gwiritsani ntchito tepi yofiyira kuti mugwirizanitse matabwa a unit, ndi kuchotsa ma burrs kudzera pamzere wa alkaline etching.

10. Pambuyo pakuyika kwachiwiri kwa mkuwa ndi malata pa gawo lapansi, dzenje lozungulira pamphepete mwa bolodi limadulidwa pakati kuti likhale theka la dzenje, chifukwa mkuwa wa khoma la dzenje umakhala wokutidwa ndi malata, ndipo mkuwa wosanjikiza wa dzenje khoma ali bwinobwino ndi wosanjikiza mkuwa wa wosanjikiza akunja kwa gawo lapansi Connection, okhudza amphamvu kugwirizana mphamvu, angathe kuteteza wosanjikiza mkuwa pa dzenje khoma kuti anakokedwa kapena mkuwa warping pamene kudula;

11. Pambuyo kupanga theka-bowo kumalizidwa, filimuyo imachotsedwa ndiyeno inakhazikika, kotero kuti pamwamba pa mkuwa sadzakhala oxidized, mogwira kupewa kuchitika kwa mkuwa wotsalira kapena dera lalifupi, ndikuwongolera zokolola za theka lazitsulo. -bowo PCB dera bolodi.

FAQs

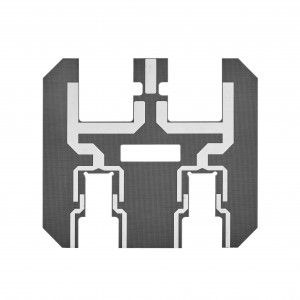

Bowo lokutidwa ndi theka kapena dzenje lopangidwa ndi castelated, ndi m'mphepete ngati sitampu podula pakati pa autilaini.Bowo lopukutidwa ndi gawo lapamwamba la m'mphepete mwa matabwa osindikizidwa, omwe nthawi zambiri amagwiritsidwa ntchito polumikizira bolodi ndi bolodi.

Via imagwiritsidwa ntchito ngati cholumikizira pakati pa zigawo zamkuwa pa PCB pomwe PTH nthawi zambiri imapangidwa kukhala yayikulu kuposa vias ndipo imagwiritsidwa ntchito ngati dzenje lodzala kuti avomereze zitsogozo zamagulu - monga otsutsa a SMT, ma capacitors, ndi phukusi la DIP IC.PTH itha kugwiritsidwanso ntchito ngati mabowo olumikizira makina pomwe vias sangatero.

The plating pa mabowo ndi mkuwa, kondakitala, kotero amalola madutsidwe magetsi kuyenda bolodi.Osakutidwa kudzera m'mabowo alibe conductivity, kotero ngati muwagwiritsa ntchito, mutha kukhala ndi mayendedwe amkuwa othandiza mbali imodzi ya bolodi.

Pali mitundu ya 3 ya mabowo mu PCB, Plated Through Hole (PTH), Non-Plated Through Hole (NPTH) ndi Via Holes, izi siziyenera kusokonezedwa ndi Mipata kapena Kudula.

Kuchokera muyeso wa IPC, ndi +/-0.08mm ya pth, ndi +/-0.05mm ya npth.